The Nine Well Plate Characteristics of BRANDplates Microplates

Microplates are available with a variety of different well plate characteristics such as plate type, material of construction and surface treatment. Different combinations of these well plate characteristics create the broad product range of BRANDplates® microplates.

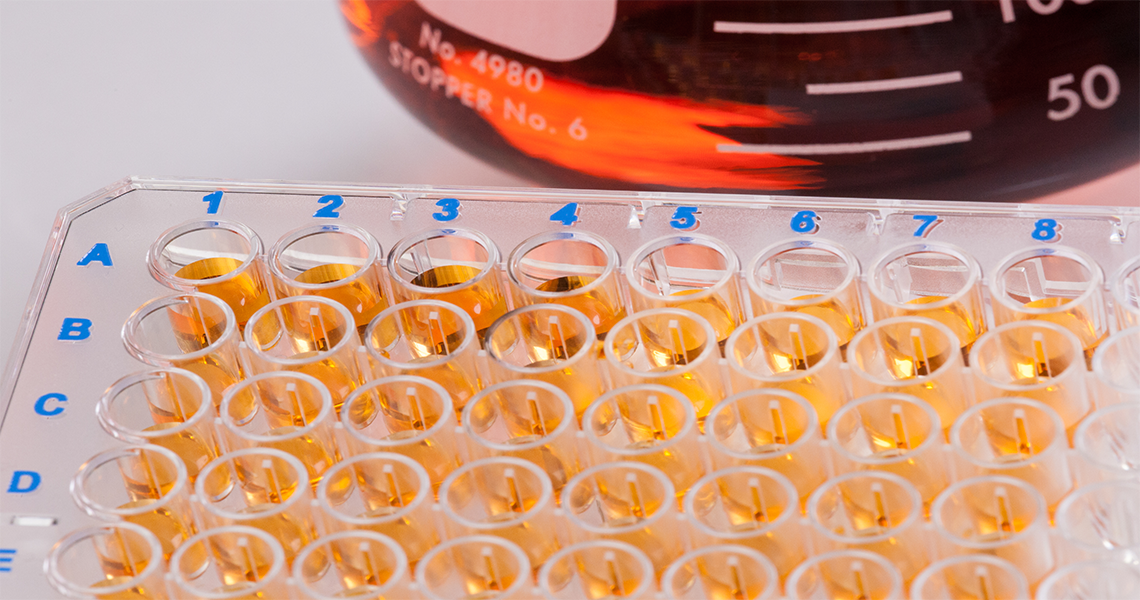

BRANDplates microplates are offered in 96-, 384-, and 1536-well formats. Well geometry is an important well plate characteristic. BRANDplates® microplates 96-well format are manufactured with a “chimney well” design. Each individual well is separated from each other with a gap to reduce cross contamination risk. In combination with the condensation rings of the lid, evaporation is reduced substantially. In the 384- and 1536-well formats, rounded wells allow optimal uniform meniscus formation.

The selection of the correct raw materials is a crucial step when manufacturing premium quality products. Not only are the physical and chemical properties critical in the field of microplate production, the optical well plate characteristics of the end product are also crucial. BRANDplates® microplates are manufactured of polystyrene (PS), uncolored PS provides high transparency with optimal optical characteristics, making it especially suited for colorimetric assays and other optical characteristics.

3. Plate Types

Construction and shape of the microplates define the different plate types. BRAND microplates are available in two different plate types.

Standard Microplates

Standard plates are available in all formats (96-, 384- and 1536-well).

Microplates With Transparent Bottom

These plates are available in 96- and 384-well formats. They are manufactured out of white or black PS, with a transparent bottom made of PS.

4. Colors

The application to be performed in the plate generally determines the color of the plates used. A basic rule is: transparent for colorimetry; white for luminescence; and black for fluorescence. BRANDplates® microplates are available in three colors, transparent, white and black.

5. Bottom Shapes Of 96-Well Plates

The 96-well format microplates are available in four distinct bottom shapes. The 384-well and the 1536-well microplates are only available with the F-bottom.

- U-bottom; round-shaped well bottom.

- V-bottom; conically-shaped well bottom.

- F-Bottom; flat well-bottom.

- C-Bottom; flat bottom with curved edges.

6. Color Codes For The 96-Well Plates

To enable an easy identification of the surface type and to facilitate the legibility of the alphanumeric coding, most BRANDplates® microplates in the 96-well format have a color-coding embossing.

- Grey coded; non-treated standard microplates

- Blue coded; standard microplates for immunological applications

- Orange coded; standard microplate for cell culture applications

7. Surfaces

BRANDplates® microplates are offered with nine different surfaces.

- Non-Treated Surfaces; sterile and non-sterile.

- Immunoassay Surfaces; available in three different non-sterile surfaces.

- Cell Culture Surfaces; available in four different sterile surfaces.

8. Barcode

Upon request, BRAND can provide high-quality barcode printing directly to the plate. To learn more about the barcode options please contact us directly for order quantities and lead times.

9. Lids & Films For Microplates

There are a variety of polystyrene lids available for all BRANDplates® designed to protect samples from evaporation and contamination.

There are many factors to consider when reviewing well plate characteristics and determining the right microplate for your application. There is no substitute for direct experience, that is why we are proud to offer a sample program for our customers.